Insulating the attic of a lightweight structure house with open-cell spray foam is an efficient and innovative solution for achieving...

Professional insulation of buildings with sprayed polyurethane foam

Professional insulation of buildings with sprayed polyurethane foam

Spray foam insulation, like other insulation types, saves energy costs and reduces utility bills. Buildings treated with foam insulation insulate 50% better than those using traditional insulation products. Properly applied insulation can serve as a defense against moisture, reducing the appearance of harmful mold and the chance of wood decay. In addition to regulating building temperature and moisture, spray foam insulation is often employed for noise reduction. It acts as a barrier to airborne sounds, reducing airborne sound transmission through the building’s roof, floor, and walls compared to an uninsulated structure.All types of insulation prevent energy loss. Some types, including spray foam, also seal air leakage. Insulation contributes to energy savings even in warm climates by reducing the need for climate control.

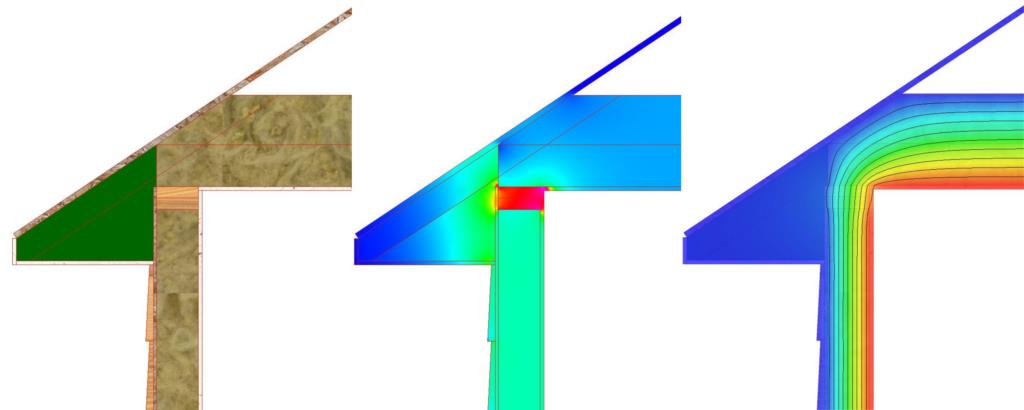

Bonded board insulation materials become thermally inefficient over time as they compact, separating from each other and the underlying surface, causing increasingly larger gaps for air to penetrate. In contrast, sprayed polyurethane foam adheres to the underlying surface, forming a continuous layer that insulates the surface without creating thermal bridges. In case the underlying surface has any imperfections or cracks, the foam fills those areas, sticking the surfaces together, ensuring maximum effectiveness.

When constructed with a thickness of at least 140 mm, it functions as an airtight barrier. It is commonly used for interior walls, providing sound reduction by blocking and absorbing air leakage. Generally recommended for indoor use only.

Speaking of a well-established technology, with the right equipment and expertise, the insulation of vast surfaces can be achieved daily. Following the cleaning of the surface to be insulated, the insulation material can be applied immediately, without any additional processes such as gluing, cutting to size, or attaching foil. Thanks to this, we can undertake insulation projects for large surfaces within a relatively short timeframe.

Insulating the attic of a lightweight structure house with open-cell spray foam is an efficient and innovative solution for achieving...

Insulating the roof rafters with open-cell spray foam provides an innovative solution for optimal thermal insulation and efficient use of...

Insulating an attic with open-cell spray foam is an effective solution for the attic space, providing excellent thermal insulation and...

Purfoam is a chemical product made up of two substances, isocyanate and polyol resin, which react when mixed with each other and expand to 30-60 times the volume of the liquid when sprayed into place. This expansion makes the blown mixture particularly useful, as it molds the shape of the surface to be insulated while providing a high thermal insulation value with virtually no air infiltration.

Otto Bayer is credited with the invention of polyurethane in 1937. He succeeded in synthesizing polyurethane foam by exploring his basic idea that dry foam materials could be created by mixing small amounts of chemicals. Polyurethane has been further developed for a variety of applications, from shoe soles and cushions to industrial uses. In the 1940s, rigid foam was used in airplanes, and in 1979, polyurethane began to be used to insulate buildings.

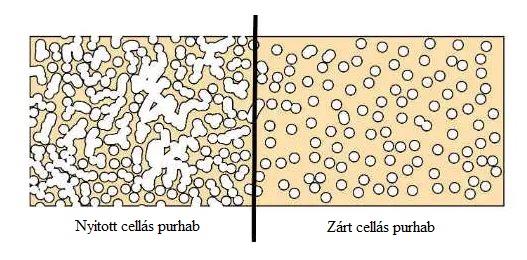

The heat resistance. The R-value is a term given to thermal resistance to heat flow. The higher the R-value of an insulation product, the more effective its insulating properties. Sprayed polyurethane foam is available in different densities and cell structures. Low-density foams are called open-cell foams, while higher-density foams are called closed-cell foams. Polyurethane foam has the highest R-value among insulation materials that can be used in homes and buildings. Polyurethane is a closed-cell foam insulation material that contains a low-conductivity gas in its cells. Due to the high thermal resistance of the gas, the initial R-value of sprayed polyurethane insulation is typically between R-3.4 and R-6.7 per inch. In comparison, glass wool typically has an R-value of only R-3 to R-4 per inch.

Spray polyurethane foam insulation can be classified into two different types: light density open cell spray foam insulation and medium density closed cell spray foam insulation. Both types of foam are thermosetting cellular plastic containing millions of small cells. Open cell insulation can be crushed in the hand and has a lower insulation value. The closed cell is stiff to the touch and all air cells are completely sealed. While closed-cell foam has a higher R-value, it is more expensive to purchase.

Medium-density closed-cell foam insulation is a rigid insulation material with a long-term thermal resistance R-value of 5.1 to 6 inches. If the required minimum thickness of 50 mm is built, this material is both a vapor barrier and an air barrier. The natural color of foam is usually yellow.

Light-density, open-cell foam insulation is a semi-rigid material with a spongy appearance that expands during installation to create small, open cells that are filled with carbon dioxide. Thanks to its ability to expand during the application process, it fills cracks, gaps and voids and forms an adhesive and airtight insulation for uneven surfaces or substrates. While the R value can vary, most open-cell purfoam products have an R value of about 3.8 per inch. Unlike medium-density closed-cell foam, the thinner layers of ocSPF are not very effective as a vapor barrier because air seeps through the open-cell structure. However, if it is built to a thickness of at least 140 mm, it already works as an air barrier. It is often used for interior walls because it provides sound reduction by blocking and absorbing air leakage. Generally recommended for indoor use only.